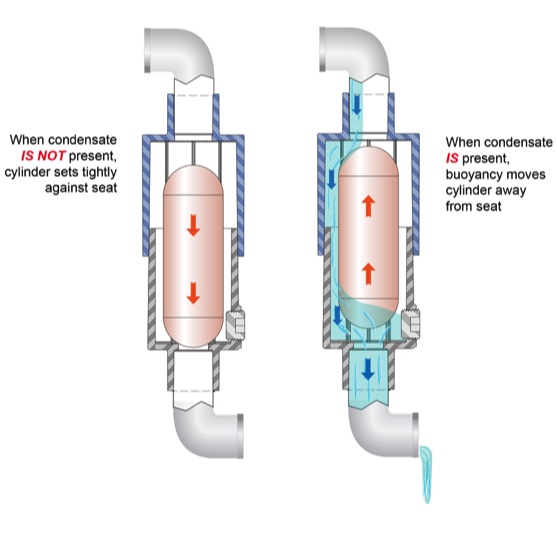

The Air-Trap allows liquid condensate to drain from the HVAC equipment and simultaneously prevents air from entering or escaping from the equipment.

P-Series in Operation

A video highlighting the operation of the P-Series installed in a positive pressure orientation.

P-Series Positive Orientation Animation

An animation detailing P-Series concept for a positive pressure installation.

¾" 1" 1¼" 1½" Clear

Why a Waterless Trap?

Note: The attached drawings represent traps that operate under positive pressure. Never connect condensate drain directly to a sanitary drain line.

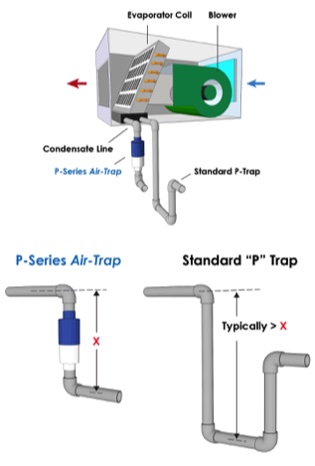

Typically, HVAC equipment is fitted with “P” traps that require water, or another liquid, within a standpipe to prevent gas from entering or leaving the unit. As a result, the “P” traps are susceptible to freezing - expansion - bursting. At other times, the traps dry out allowing gas to escape or enter the HVAC equipment. The Air-Trap never requires addition of water to prevent unwanted air leakage.

• The Air-Trap allows water to drain from the HVAC equipment.

• Prevents air from entering or escaping from the equipment.

• The Air-Trap operates dry when no water removal is required and wet when it is required.

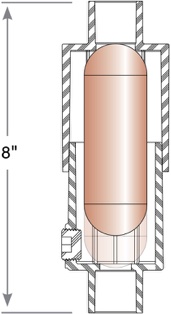

P-Series

P-Series Videos

Positive Pressure Waterless Trap

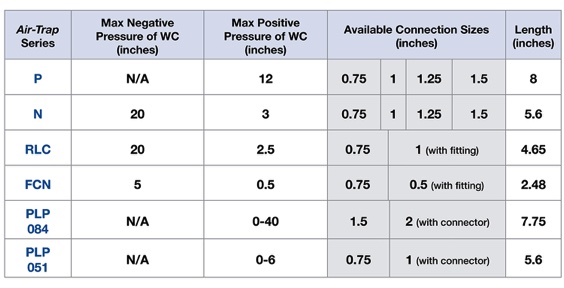

Maximum Pressures, Connection Sizes & Length

Click below button to see available sales locations and distributors

or purchase the P-Series below using the secure checkout from our Shopify store, waterless-trap.com

HVAC Air-Trap

• Operates Dry — Eliminating:

- Freezing and breaking

- Dryouts

- Sludge buildup

- Geyser effect

- Mold and mildew caused by geyser effect

• Prevents air leakage

• Reduces trap height requirement by 1/2

• Predesigned — eliminating field-designed errors

No More Troublesome "P" Traps

Positive Pressure Orientation

P-Series Operation

• P-Series Air-Trap requires no water head to cause the trap to operate. Simply come out of the plenum condensate line and go down into the P-Series Air-Trap. Come out of the trap and go horizontally with your drain line. The height requirement then becomes the height of the trap plus two elbows.

• When removing water, the water exits the unit but no air escapes the unit.

• Reduces sludge buildup that normally accumulates in standard “P” traps.

• Prevents problem with standard “P” trap never filling with water when condensate begins to form at the beginning of the cooling season.

• Prevents freezing of trap during cold periods since there is no water in the trap.

Features

• Schedule 40 PVC with clean out port

• Retains no water after condensing has ceased

• Requires no water head to cause trap to operate

• Meets general building codes. For use on HVAC equipment only. Not for use as a sanitary trap.

Specifications

Maximum negative pressure of WC N/A

Maximum positive pressure of WC 12"

Maximum Condensate Flow, GPM (all connection sizes):

Any Negative Pressure:

N/A

Positive Pressure:

0.5 at 12" WC

1.0 at 8" WC

1.5 at 7" WC

2.0 at 4" WC

Length 8"

Flammability rating is UL94 V-0

Air-Traps Meet IMC® Code Section M307.2.4.1

Available Models and Connection Sizes

¾" 1" 1¼" 1½" White

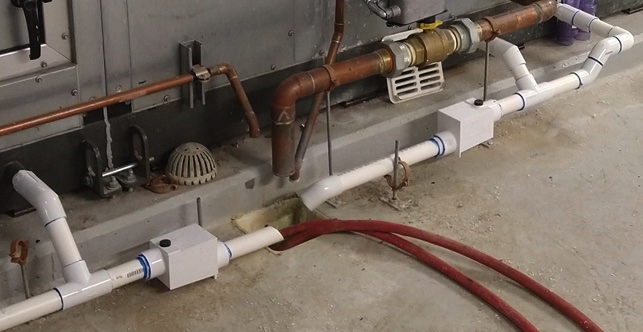

P-Series Installations

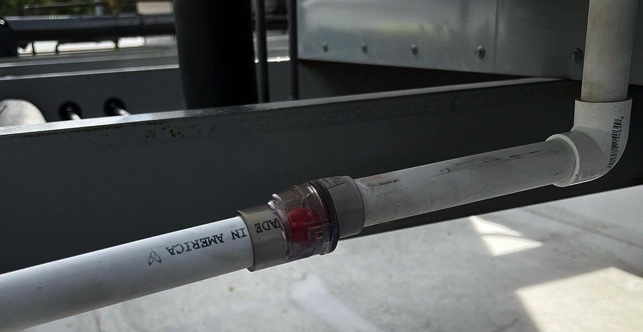

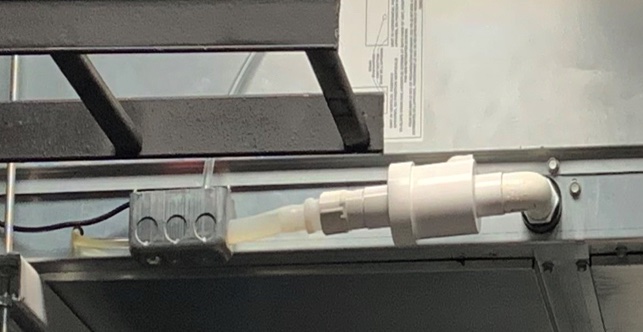

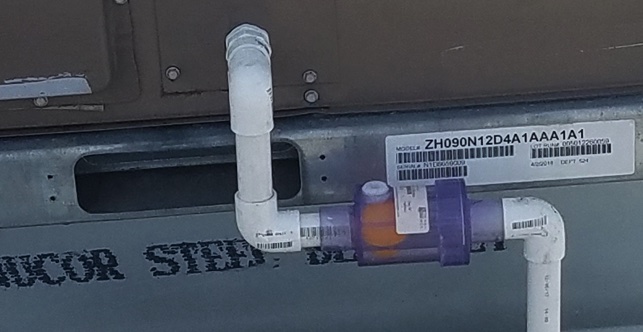

P-Series commercial positive pressure internal installation.

P-Series commercial positive pressure installation directly into schedule 80 PVC.

Patented: US9777957B1